This machine relies on magnetic induction to heat up either the core of an hollow tie rod or directly the nuts generally found on turbine casings. This process is accomplished thanks to special auto-cooling inductors, which are custom build on specific request (eg. diameter, lenght, heating lenght, etc.).

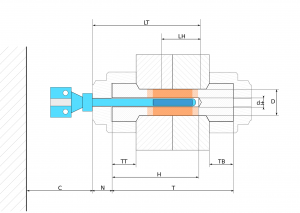

In this case, a linear inductor is introduced into an hollow tie rod. The machine is turned on and the magnetic field starts to heat up the core of the tie rod. We know for sure how long we need to heat and the exact lenght on which is it possible to apply heating without providing damages to the thread, a very delicate part. This process results into an elongation of the tie rod and, subsequently, the following scheme sums everything up:

d± : hole diameter and tolerance;

D : external bolt diameter;

T : total bolt length;

H : hole depth in case of blind-hole (In case of through-hole: H=T).

TT : top side threaded length;

TB : bottom side threaded length;

This tipe of inductor can be applied directly on the nuts to accomplish bolting or unbolting. The process is pretty much the same.

Starting from how easily it gets to how effective and innovative it is, this machine surprices for it’s small dimensions and its outstanding heating power.

Maybe the most important feature of this machine. Its compactness. It just stands in 1 squared meter and relies on just few cables, one for functioning and the other for energy acquisition. Other machines need external source of cooling liquid, which are, most of the times huge and steal much of the space.

Yes, this method is as effective as easy to be used. The training for the operators lasts just one day, in which it is possible to understand the whole capabilities of the system. This new version has been implemented with a digital display, which unlocks several other features as process controlling and monitoring.

Another important feature is the possibility to customize the inductors (candles, ring-shaped inductors) as it is required by the specific application. It doesn’t matter about diameters, lengths and so on, a customized solution is possibile by following compiling this document or by directly asking to our technical department.